For Production Work Which Electrode Size Should Be Used

62Stick Electrode KeyPlayersinNorthAmerica2019-2022 63NorthAmericaStick Electrode MarketSizebyType2015-2022 64NorthAmericaStick Electrode MarketSizebyApplication2015-2022 7Europe. Metal-electrolyte reactions electrode circuits for neural stimulation.

Electrode Size An Overview Sciencedirect Topics

First you need a largerdiameter tungsten electrode to carry for example 200 amps AC than you would to carry 200 amps DC see Figure 1.

. The traditional solution to this is not to grind a point on the tungsten. The ER4043 is the most commonly used MIG filler wire. One of the best rated 7014 rods is the Hobart 770465.

Geschke in 4M 2006 - Second International Conference on Multi-Material Micro Manufacture 2006 22 Laser ablation of electrodes. Minimize warming the treatment area of the body prior to stimulation so there is minimal increased resistance. When arc blow is a problem either use AC or limit the current.

One more factor to consider is production. The stick electrode used in an application can have a significant impact on the quality of the final weld. Cleaning the patients skin with alcohol to remove oil and dirt before electrode application.

However all refillable ROSS electrodes will use a 3M KCl outer reference solution. Joint dimensions also sometimes limit the electrode diameter that will fit into. In vertical down welding incline the outer end of the electrode downward about 15 degrees from the horizontal while keeping the arc pointing upward.

If the environment has low or high-temperature shock waves the best to use is a low hydrogen electrode like E7018 which are also known as basic electrodes. In welding upward you should hold the electrode at 90 degrees to the vertical as shown in figure 7-36 view A. When weaving is necessary oscillate the electrode as shown in figure 7-36 view B.

The tungsten electrode is the crucial carrier in the welding process and must be ground and cut properly. For instance if there are two electrodes with 4 salt one wet gel and one solid gel the wet gel would be more reactive. Properly ground and cut electrodes improve arc starting and stability.

An improperly prepared electrode leads to arc wander splitting shedding inconsistencies or expensive mistakes. Working and auxiliary electrodes were laser welded from a PMMA sheet with a PB doped PEDT film. The choice between electrodes should then be determined based off of testing criteria and duration.

Consideration of these factors is a good start to overcoming the challenge of selecting the correct stick electrode for a particular job. These types of. Solid gels are easier on the skin than wet gels due to superior water content in wet gels that react aggressively on the skin.

Electrode type Select proper electrode for each job based on the type of base metal expected service and mechanical properties required. Have provided comprehensive details related to the electricity production from both microalgae C. It welds aluminum grades 5050 5052 5056 5083 5086 5154 5356 5454 5456.

The laser used was a CO 2 laser Synrad WA USA with wavelength of 106 μm and the power was modulated to remove the. The iodideiodine internal reference combined with a platinum wire creates a redox potential. I have seen a large variety in electrode size used by different therapists from the small self adhesive electrodes 5cmx5cm to the larger round 75mm or 50x50mm or 90x50mm.

In most cases the gas used is always 100 Argon and in rare cases a heliumArgon mix may be used on base metals thicker than ½ of a inch. How current flows through electrolytic fluids 1108 update Topics. Full size electrodes are generally used in job shops where many different parts can be run on the same electrode and or many short runs are anticipated.

Any electrode touching tissue for recording should minimize its influence on the tissue. Metal - Aqueous interface. Second if you grind the tungsten to a point and use it in AC welding the tip rapidly deteriorates.

Electrode size Electrode size should depend on the electrode type welding position joint. In general the maximum electrode size practical for vertical and overhead welding is 316 with 532 electrode being the maximum size for low hydrogen electrodes. When using electrotherapy on horses the distance between electrodes can be much bigger than on humans and you are also trying to treat a larger area.

The electrodes designation is as follows. Most electrodes used for biopotential recording are AgAg-Cl. Clipping excess body hair under electrodes.

This allows for a faster response and better stability over time than an electrode with a silver wire and the traditional AgAgCl complex fill solution. If working in flat positions an E7014 or E7024 electrode should be used. Popular Answers 1 For electrolytic cells the choice of electrode material depends on the ions present in the electrolyte and which ions you wish to be discharged at the cathode and anode.

A conductive pathway - including electrodes leads and a conductive surface with good contact. Figure 1Electrode geometry comprises three factors. This means two things.

The choice of cap vs full size standard electrode comes down to job shop frequent set ups and length of production runs. High DC current increases arc blow. When the electrodes are applied chemical reactions at the surface of the electrodes must occur to allow electrical currents to flow between the subject and the equipment.

These reactions cause the electrode surface to slowly degrade over time. While many fabricators have turned to wire welding processes to speed production and. Caps are the choice for long runs or in highly automated facilities.

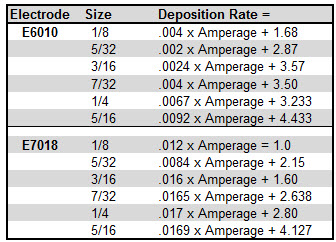

Deposition Rates For Stick Electrodes Welding Answers

Electrode Size An Overview Sciencedirect Topics

Aluminum Workshop Choosing Tungsten Electrode Type Size For Aluminum Tig

No comments for "For Production Work Which Electrode Size Should Be Used"

Post a Comment